The Art of Brake Rotor Resurfacing: Unveiling the Power of Brake Lathes

As the sun peeked over the horizon, illuminating the bustling streets of Orange County, I couldn’t help but feel a sense of excitement. You see, I’m not your average car enthusiast – I’m the proud owner of an RV and fleet vehicle repair company, and today, I’m about to dive deep into the world of brake lathes and rotor machining.

Now, I know what you’re thinking: “Brake lathes? Rotor machining? That sounds like a snooze-fest.” But hold on to your seatbelts, my friends, because I’m about to take you on a thrilling journey through the heart of automotive maintenance and repair. Trust me, by the time we’re done, you’ll be dreaming of the day you can get your hands on the best brake lathe for your next rotor resurfacing project.

The Importance of Precise Rotor Machining

Let’s start with the basics: why is rotor machining such a big deal, anyway? Well, my friends, the answer lies in the sheer importance of your vehicle’s braking system. Think about it – when you’re hurtling down the highway at 70 mph, the last thing you want is for your brakes to fail. And that’s where the humble brake rotor comes into play.

The brake rotor is the heart of your vehicle’s braking system, responsible for slowing down and stopping your car or RV. But over time, these rotors can become warped, uneven, or simply worn down, leading to a host of problems, from shaky, unresponsive brakes to the dreaded “brake shudder.”

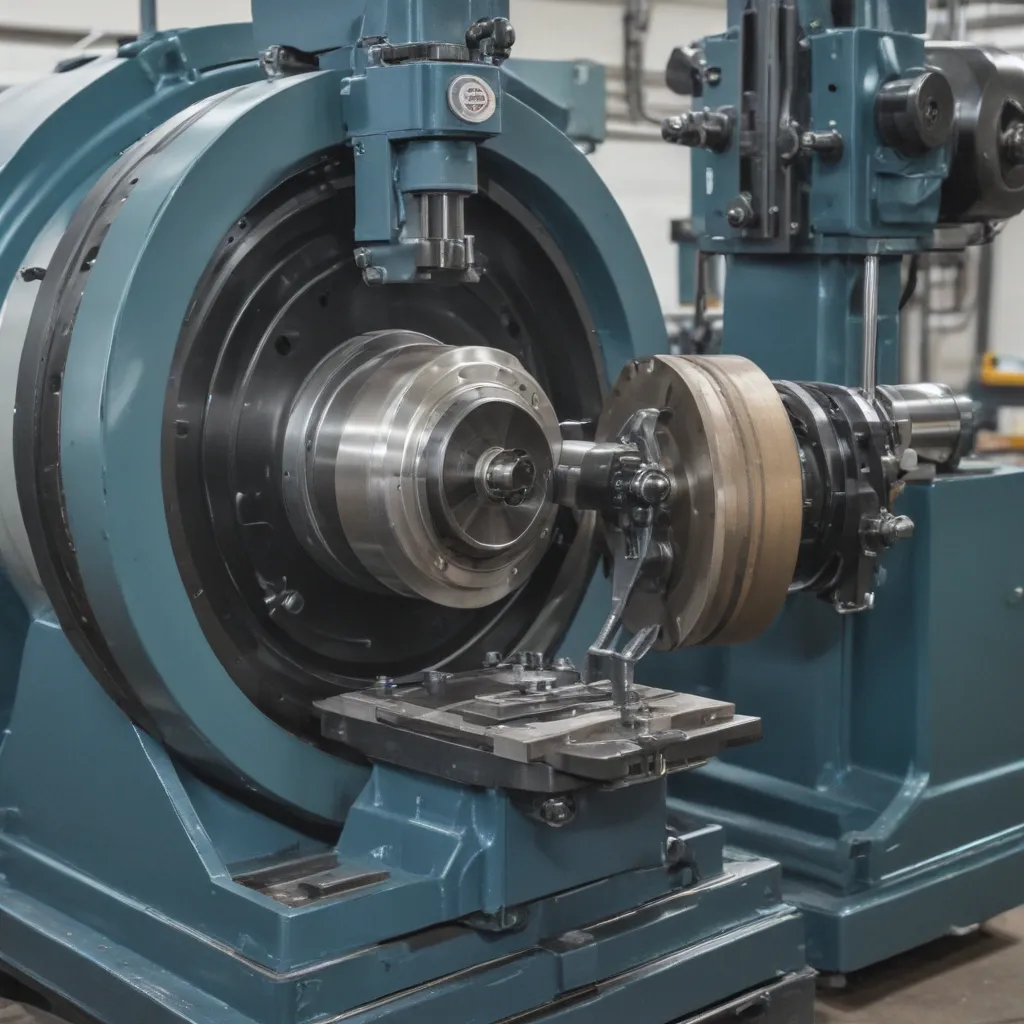

That’s where rotor machining comes in. By using a high-precision brake lathe, experienced technicians can carefully resurface your rotors, restoring them to their former glory and ensuring that your brakes perform at their absolute best. And when it comes to brake lathes, not all machines are created equal.

Navigating the World of Brake Lathes

Now, you might be wondering, “What makes a brake lathe so special?” Well, my friends, let me tell you – these machines are the unsung heroes of the automotive world. They’re not just some run-of-the-mill power tool; they’re precision instruments, designed to work their magic on your vehicle’s rotors with the utmost care and attention.

But with so many different brake lathe models out there, how do you know which one is right for your needs? That’s where my expertise comes in. As the owner of an RV and fleet vehicle repair company, I’ve had the privilege of working with a wide range of brake lathes, and I’ve seen firsthand the difference that a quality machine can make.

Top-Rated Brake Lathes for Rotor Machining

Now, let’s dive into the nitty-gritty of some of the top-rated brake lathes on the market. I’m talking about the crème de la crème, the heavy-hitters, the ones that’ll make your rotor resurfacing dreams come true.

First up, we have the Ammco 4000 Brake Lathe. This bad boy is the workhorse of the industry, designed to handle even the most stubborn and warped rotors with ease. It boasts a robust construction, precision accuracy, and the kind of power that’ll make your jaw drop. I’ve personally used the Ammco 4000 on countless RV and fleet vehicle projects, and let me tell you, it’s a game-changer.

But if you’re looking for a bit more advanced features, the Accu-Turn 8900 Brake Lathe might be more your speed. This cutting-edge machine comes equipped with all the bells and whistles, from automatic feed and depth control to an intuitive touchscreen interface. It’s the kind of brake lathe that’ll make you feel like you’re operating a high-tech spaceship, rather than a humble automotive tool.

And let’s not forget the Ranger R980 Brake Lathe. This beauty is the perfect blend of power and precision, with a heavy-duty design that can handle even the toughest rotor resurfacing jobs. Plus, with its user-friendly controls and easy-to-read display, even the most novice technician can feel like a pro when using this bad boy.

The Importance of Calibration and Maintenance

Now, as impressive as these brake lathes may be, it’s important to remember that they’re not just plug-and-play devices. To keep them running at their best, they require regular calibration and maintenance. And trust me, I’ve seen my fair share of horror stories when it comes to neglected brake lathes.

Imagine this: you’ve got a fleet of RVs that need their rotors resurfaced, so you bring in your trusty brake lathe. But as soon as you start the machine, you notice something’s off – the rotor isn’t being machined evenly, and the surface finish is less than stellar. What gives?

Well, my friends, it all comes down to calibration. You see, these precision instruments need to be fine-tuned on a regular basis to ensure that they’re delivering the kind of accurate, consistent results that you need. And if you skip this crucial step, you’re just asking for trouble.

But it’s not just calibration that’s important – proper maintenance is key as well. These brake lathes are workhorse machines, and they need to be treated with the utmost care and attention. From regularly cleaning and lubricating the moving parts to replacing worn-out components, there’s a whole lot of TLC that goes into keeping these babies running at their best.

The Importance of Training and Expertise

Now, I know what you’re thinking: “This all sounds like a lot of work!” And you’re absolutely right. Properly maintaining and operating a high-quality brake lathe is no easy feat. It takes time, effort, and a whole lot of expertise.

That’s why, when it comes to rotor machining, it’s so important to work with a team of experienced, well-trained technicians. These are the folks who know the ins and outs of these machines, who can spot potential issues before they become major problems, and who can deliver the kind of precision and attention to detail that’ll keep your vehicles on the road and your customers happy.

At my RV and fleet vehicle repair company, we take pride in our team of skilled technicians. They’ve been through rigorous training on the latest brake lathe technologies, and they’re constantly staying up-to-date on the latest industry developments. And let me tell you, the results speak for themselves. Our customers consistently rave about the smooth, seamless braking performance of their vehicles, all thanks to the hard work and dedication of our top-notch team.

The Future of Brake Lathes and Rotor Machining

As we look to the future, it’s clear that the world of brake lathes and rotor machining is only going to continue to evolve. With advancements in technology, we’re seeing the emergence of ever-more-sophisticated machines, with features like wireless connectivity, automated diagnostics, and even remote troubleshooting capabilities.

And you know what that means? It means that the bar for excellence in this industry is only going to keep getting higher. Gone are the days of the old, clunky brake lathes of yesteryear – these new machines are sleek, powerful, and incredibly precise, capable of delivering results that’ll leave your customers awestruck.

But you know what else it means? It means that the importance of proper training and expertise is only going to become more crucial. As these machines become more advanced, it’s going to take a special breed of technician to truly master their operation and maintenance. And that’s where my RV and fleet vehicle repair company comes in – we’re always on the cutting edge, investing in the latest technologies and ensuring that our team is up to the task.

Conclusion: The Future is Bright for Brake Lathes and Rotor Machining

So there you have it, my friends – the inside scoop on the world of top-rated brake lathes and the art of rotor machining. From the importance of precision and the power of these incredible machines to the crucial role of calibration, maintenance, and expert technicians, I’ve covered it all.

But you know what the best part is? The future is bright for this industry. As technology continues to evolve and the demand for high-quality braking systems only increases, the need for skilled brake lathe operators and rotor machining experts is only going to grow. And that’s music to the ears of someone like me, who’s dedicated their life to keeping the wheels turning and the brakes in tip-top shape.

So, if you’re in the market for a brake lathe or you’re looking to get your rotors resurfaced, I can’t recommend enough that you work with a team of experienced professionals. Trust me, the difference it’ll make in the performance and longevity of your vehicle will be nothing short of astounding.

And who knows – maybe one day, you’ll even find yourself dreaming of the day you can get your hands on the latest and greatest brake lathe technology. After all, in this industry, the future is bright, and the possibilities are endless.