Why Test Each System Individually?

As the owner of an RV and fleet vehicle repair company in Orange County, California, I can’t stress enough the importance of testing each system individually for faults. Sure, you could just blindly start swapping out parts until something magically starts working again, but where’s the fun in that? Plus, that method is a surefire way to drain your wallet and waste a whole lot of time.

Think about it this way – your RV or fleet vehicle is like a finely tuned orchestra, with each component playing a crucial role in the overall performance. If one section is out of tune, the whole thing is going to sound like a cat being dragged through a saxophone solo. You wouldn’t just start randomly replacing instruments without first identifying the root of the problem, would you? Of course not! So why would you take that approach with your vehicle?

By testing each system individually, you can pinpoint the exact issue and address it with a targeted solution. It’s like being a medical detective – you start with the symptoms, run some tests, and then prescribe the appropriate treatment. Trust me, it’s a whole lot more effective than just throwing a bunch of random pills at the problem and hoping for the best.

The Benefits of Systematic Troubleshooting

Now, I know what you’re thinking – “But Jared, testing each system individually sounds like a huge pain in the butt!” And you’re not wrong, it can be a bit of a time-consuming process. But the payoff is so worth it, I promise. Let me break down the benefits for you:

Improved Efficiency: When you test each system individually, you can quickly identify the root cause of the issue and address it directly, rather than wasting time and resources on trial-and-error repairs.

Cost Savings: By targeting the specific problem, you’ll avoid the need to replace unnecessary parts, which can add up to significant cost savings over time.

Better Diagnostics: Systematic troubleshooting allows you to gather more detailed information about the condition of your vehicle, which can help you make informed decisions about future maintenance and repairs.

Prolonged Vehicle Lifespan: By addressing issues early on and preventing them from cascading into larger problems, you can extend the lifespan of your RV or fleet vehicle and get the most out of your investment.

Peace of Mind: Knowing that your vehicle has been thoroughly tested and any issues have been properly addressed can provide a sense of security and confidence when you hit the road.

The Step-by-Step Process

Okay, now that you’re convinced of the benefits, let’s dive into the nitty-gritty of how to actually test each system individually. I like to break it down into a simple, five-step process:

Gather Information: Start by gathering as much information as possible about the issue you’re experiencing. What symptoms are you seeing? When does the problem occur? Have you made any recent changes or modifications to the vehicle? This information will help you narrow down the potential causes.

Identify the Systems Involved: Next, identify which specific systems in your RV or fleet vehicle might be contributing to the problem. This could include the electrical system, the brakes, the engine, the suspension, or any number of other components.

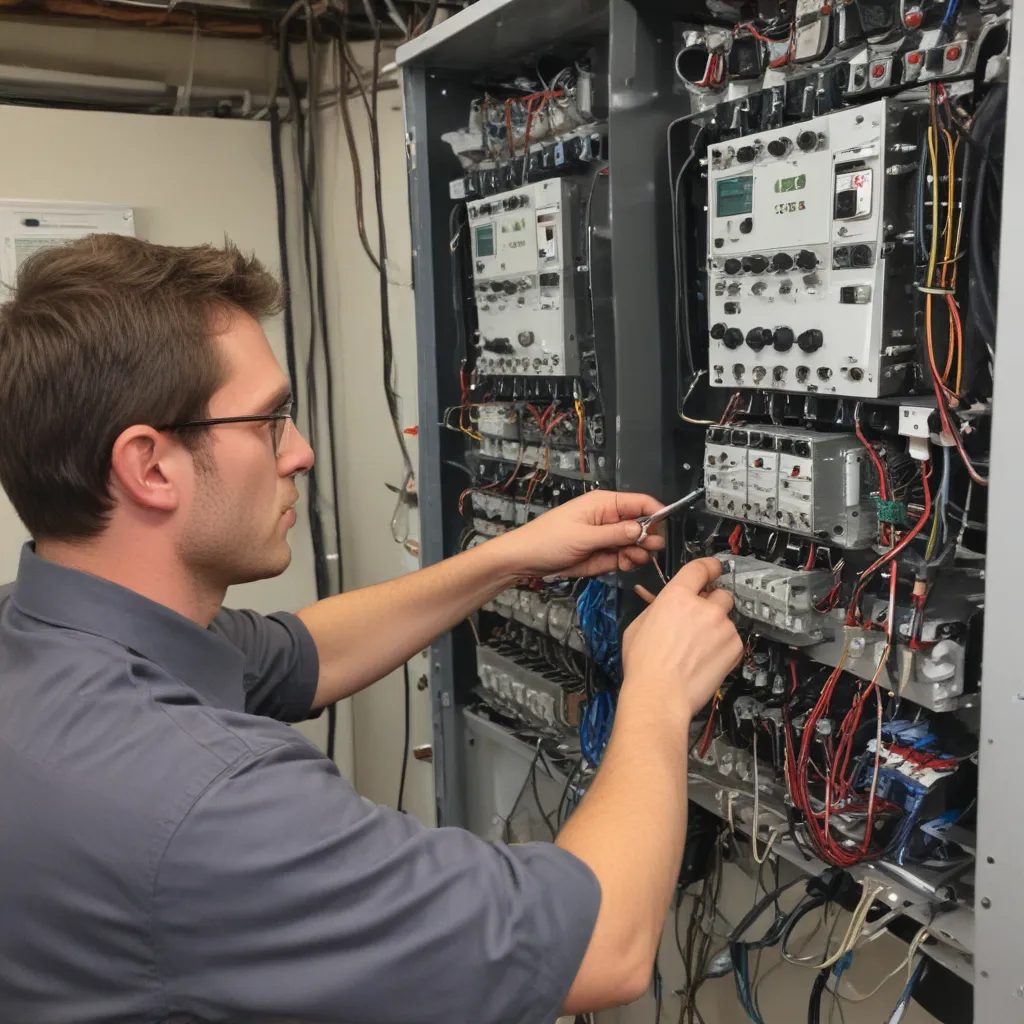

Test Each System: Now it’s time to test each system individually. This might involve using diagnostic tools, performing visual inspections, or even running specific tests on individual components. The key is to isolate each system and identify any potential faults or issues.

Analyze the Results: Once you’ve completed the testing, carefully analyze the results. Look for any patterns or trends that might point to the root cause of the problem. Don’t be afraid to go back and re-test something if the initial results are inconclusive.

Implement the Solution: Finally, once you’ve identified the issue, it’s time to implement the solution. This might involve repairing or replacing a specific component, or making adjustments to the system as a whole. Remember, it’s always better to address the problem at the source rather than just treating the symptoms.

Real-World Examples

Now, I know all of this might sound a bit abstract, so let me give you a couple of real-world examples to help illustrate the process:

Example 1: Electrical System Issues

Let’s say you’ve been having trouble with your RV’s electrical system. The lights keep flickering, the battery keeps draining, and you’re starting to wonder if you’ve got a short circuit somewhere. Instead of just randomly replacing batteries and fuses, you decide to test the system individually.

First, you check the battery and charging system – are they functioning properly? Next, you inspect the wiring and connections, looking for any signs of wear or damage. You even use a multimeter to test the voltage and amperage at various points in the circuit.

After a thorough investigation, you discover that the alternator is on its last legs, causing the battery to not charge properly. Armed with this knowledge, you can now replace the alternator with confidence, knowing that it will address the root of the problem.

Example 2: Braking System Concerns

Perhaps you’re noticing that your fleet vehicles are taking longer and longer to come to a complete stop. Rather than just slapping on a new set of brakes, you decide to take a more systematic approach.

You start by checking the brake fluid level and condition. Then, you inspect the brake pads and rotors, looking for any signs of wear or damage. You even hook up a brake testing machine to measure the performance of each wheel individually.

Lo and behold, you discover that one of the brake calipers is sticking, causing uneven braking on that side of the vehicle. By addressing this specific issue, you can restore your fleet’s braking performance and ensure the safety of your drivers and cargo.

Conclusion

At the end of the day, testing each system individually for faults is the key to maintaining the optimal performance and longevity of your RV or fleet vehicles. It might take a bit more time and effort upfront, but the long-term benefits are undeniable.

So, the next time you’re faced with a mysterious issue, resist the urge to just start swapping parts willy-nilly. Instead, put on your detective hat, gather your tools, and methodically test each system until you uncover the root cause. Trust me, your wallet (and your sanity) will thank you.

And if you ever need a little extra help with your RV or fleet vehicle repairs, don’t hesitate to give us a call. We’re always happy to lend a hand and share our expertise. After all, that’s what we’re here for – to keep your wheels turning and your adventures rolling!