The Importance of Rotor Machining for Optimal Brake Performance

As the owner of an RV and fleet vehicle repair shop in sunny Orange County, California, I’ve seen my fair share of brake-related issues over the years. From pulsating pedals to uneven pad wear, faulty rotors are often the culprit behind these common problems. That’s why proper rotor machining is such a critical part of our vehicle maintenance and repair process.

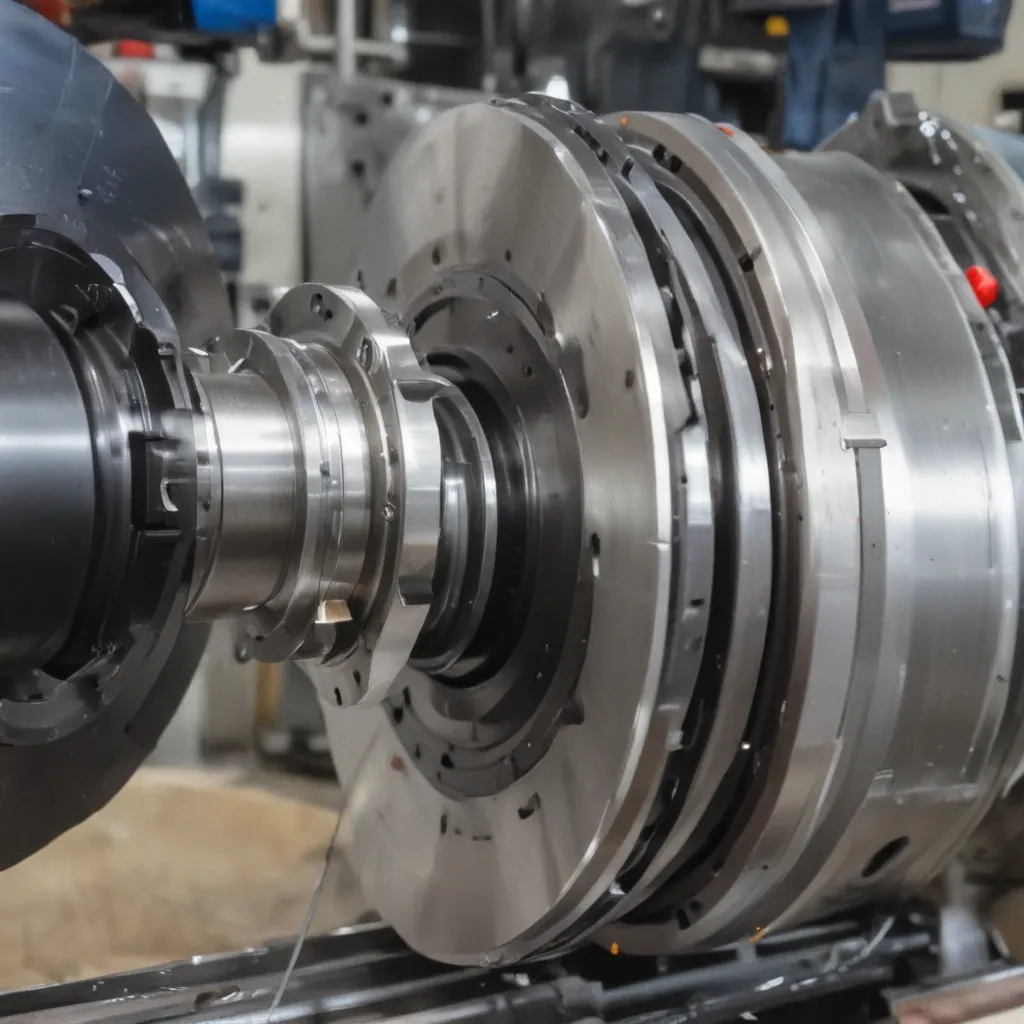

You see, the rotors – those big, shiny discs that sit behind your wheels – play a pivotal role in your braking system. They’re responsible for converting the kinetic energy of a moving vehicle into heat, allowing you to slow down and come to a stop. But over time, constant braking can cause these rotors to become warped, uneven, or glazed – reducing their effectiveness and, more importantly, compromising your safety on the road.

That’s where a high-quality brake lathe comes in. This specialized piece of equipment allows us to resurface your rotors, restoring them to their original specifications and ensuring optimal braking performance. It’s like giving your brakes a little makeover – except instead of a fancy new haircut, we’re smoothing out any imperfections and getting those rotors looking (and functioning) better than ever.

The Benefits of Rotor Machining with Premium Brake Lathes

Now, I know what you might be thinking: “Do I really need to worry about my rotors? Can’t I just slap on some new pads and call it a day?” Well, my friend, let me tell you – rotor machining is a game-changer when it comes to maintaining the health and longevity of your braking system.

For starters, properly machined rotors can significantly improve your vehicle’s braking performance. By restoring the surface of the rotor to its original specifications, we can ensure consistent, even contact with the brake pads – resulting in a smoother, more responsive pedal feel and shorter stopping distances. This not only makes your ride more comfortable, but it also enhances your safety on the road.

But the benefits of rotor machining don’t stop there. By keeping your rotors in tip-top shape, you can also extend the lifespan of your brake components. Worn or warped rotors can cause premature pad and caliper wear, leading to more frequent (and costly) replacements down the line. With regular rotor machining, however, you can help prevent this issue and save yourself a bundle in the long run.

And let’s not forget about the environmental impact. Properly maintained brakes don’t just keep you safe – they also help reduce your vehicle’s carbon footprint. When rotors are machined instead of replaced, we’re diverting tons of metal from landfills and keeping those valuable resources in circulation. It’s a win-win for you and the planet!

The Brake Lathe Difference: Why Premium Equipment Matters

Now, I know what you’re thinking: “Okay, I’m sold on the benefits of rotor machining, but do I really need a fancy, high-end brake lathe to get the job done?” The short answer? Absolutely. When it comes to rotor resurfacing, not all brake lathes are created equal.

You see, your standard, run-of-the-mill brake lathe might get the job done, but it’s like trying to bake a gourmet soufflé with a toaster oven. Sure, it’ll work, but the results won’t be nearly as impressive (or reliable). Premium brake lathes, on the other hand, are engineered to deliver precision, consistency, and efficiency that cheap, off-the-shelf models simply can’t match.

Take, for example, the advanced features of our top-of-the-line brake lathes. These bad boys are equipped with state-of-the-art CNC technology, allowing for incredibly precise and consistent rotor resurfacing. They also boast robust, vibration-dampening construction to ensure a smooth, stable finish – no more uneven, “wavy” rotors here!

And let’s not forget about the time-saving features. Our premium brake lathes are designed for lightning-fast setup and operation, with intuitive controls and automatic feed mechanisms that take the guesswork (and backbreaking labor) out of the equation. That means we can get your vehicle back on the road in a flash, without compromising on quality.

But perhaps the most important advantage of a premium brake lathe is the peace of mind it provides. When you trust your vehicle’s brakes to our shop, you can rest assured that we’re using the absolute best tools for the job. No cutting corners, no subpar workmanship – just precision, performance, and safety, every single time.

Real-World Examples: How Premium Rotor Machining Helps Our Customers

Now, I know what you’re thinking: “This all sounds great, but how do I know it actually works in the real world?” Well, let me tell you about a couple of our satisfied customers who can attest to the power of premium rotor machining.

Take, for example, the case of Jim, a longtime RV enthusiast who’s been visiting our shop for years. Jim’s beloved motorhome had been plagued by a persistent pulsating brake pedal, making long road trips a real pain (literally) in the you-know-what. After a thorough inspection, we determined that the issue was caused by warped front rotors – a common problem in heavy-duty vehicles like RVs.

Using our top-of-the-line brake lathe, we were able to precisely resurface those rotors, restoring them to their original specifications. The result? A silky-smooth pedal feel and a noticeable improvement in braking performance. Jim was so impressed that he’s been singing our praises to anyone who will listen (which, if you know RV owners, is just about everyone).

Then there’s the case of Sarah, the owner of a large fleet of delivery vans. Sarah was constantly dealing with uneven brake pad wear, which was not only costing her a fortune in replacement parts but also posing a serious safety risk to her drivers. After bringing her vehicles to our shop, we quickly identified the culprit: unevenly machined rotors.

By leveraging the precision and consistency of our premium brake lathe, we were able to restore those rotors to their optimal condition. The result? Perfectly even pad wear, improved braking performance, and a significant reduction in Sarah’s maintenance costs. Needless to say, she’s been a loyal customer ever since.

The Future of Rotor Machining: Embracing Innovation for Safer, Smoother Brakes

As an RV and fleet vehicle repair shop owner, I’ve seen a lot of changes in the industry over the years. But one thing that’s remained constant is the importance of maintaining a well-functioning braking system. And with the advent of new technologies and advanced brake lathe designs, the future of rotor machining is looking brighter than ever.

Take, for example, the integration of artificial intelligence and machine learning into brake lathe operation. Our latest models are equipped with sophisticated sensors and algorithms that can detect even the slightest imperfections in a rotor’s surface, allowing us to make micro-adjustments for a truly flawless finish. It’s like having a team of expert machinists working around the clock, without the need for coffee breaks or union negotiations.

But the innovation doesn’t stop there. We’re also seeing the emergence of hybrid and electric brake systems, which introduce a whole new set of considerations when it comes to rotor machining. These advanced braking technologies require an even higher level of precision and care, which is why we’re constantly investing in the latest training and equipment to stay ahead of the curve.

And let’s not forget about the environmental impact. As the world becomes increasingly conscious of its carbon footprint, the importance of sustainable, eco-friendly vehicle maintenance practices can’t be overstated. By keeping those rotors in tip-top shape through regular machining, we’re not only improving safety and performance but also reducing waste and resource consumption.

So, what does the future of rotor machining hold? If you ask me, it’s a bright, shiny, and oh-so-smooth one. With the continued advancement of brake lathe technology and the growing demand for safer, more sustainable transportation, I can’t wait to see what the next generation of rotor machining has in store. One thing’s for sure: when it comes to keeping your brakes in peak condition, you can count on the team at Orange County RV Repair to always be at the forefront of innovation.