Embracing the RV Revolution: A Journey Through Innovation

As the proud owner of an RV repair shop in the heart of Orange County, California, I’ve seen the industry evolve at a dizzying pace. In the not-so-distant past, keeping our fleet of recreational vehicles in tip-top shape was a labor-intensive affair, requiring countless trips to the parts store and hours of manual tinkering. But those days are quickly fading into the rearview mirror, my friends. Welcome to the future of RV maintenance, where 3D printing and advanced materials are poised to revolutionize the way we keep our homes-on-wheels running smoothly.

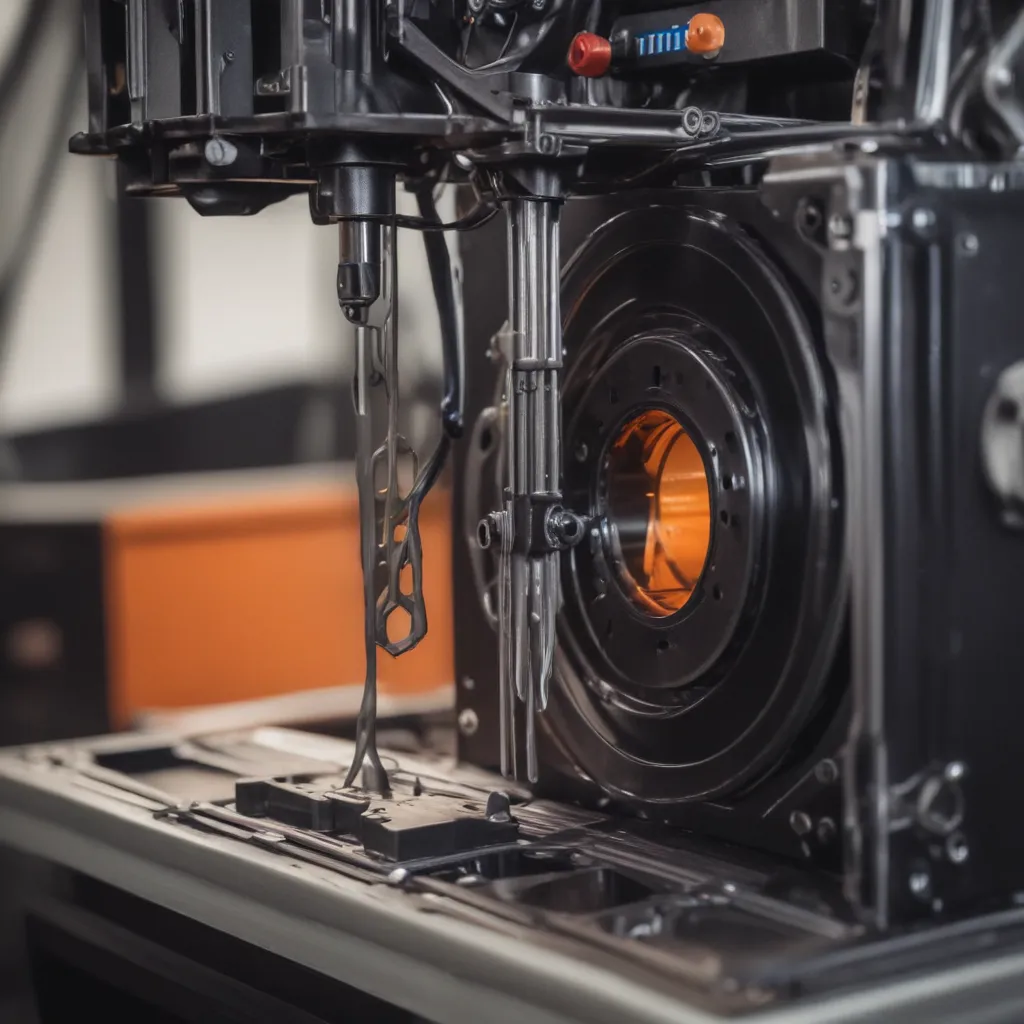

Picture this: you’re out on the open road, miles from the nearest town, and your trusty RV starts acting up. In the old days, you’d be at the mercy of whatever parts were available at the local auto shop, often leading to frustrating delays and costly repairs. But now, with the power of 3D printing on our side, we can fabricate custom parts on-the-fly, right here in our workshop. It’s like having a digital parts bin at our fingertips, ready to churn out the exact component you need, no matter how obscure or specialized.

The 3D Printing Revolution: Transforming RV Maintenance

I remember the first time I witnessed the magic of 3D printing in action. One of our regular customers, a retired couple who live full-time in their Airstream, had a rare part fail on their vintage rig. Normally, this would have meant tracking down a specialty supplier, waiting weeks for delivery, and potentially paying a premium for the privilege. But with our state-of-the-art 3D printers humming away, we were able to design and produce the replacement component in a matter of hours. The look on their faces when we handed them the freshly printed part was priceless – it was like we had performed some kind of automotive sorcery.

And it’s not just about replacing broken parts, my friends. The world of 3D printing has opened up a whole new realm of customization and personalization for RV owners. Want to upgrade your RV’s outdated cabinetry with a sleek, modern design? No problem! We can model and print custom fixtures and fittings that seamlessly integrate with your existing setup. Need a specialized mount for your oversized flat-screen TV or your fancy new satellite dish? Piece of cake. The only limit is your imagination (and maybe the size of our print bed).

Embracing Advanced Materials: Stronger, Lighter, and More Resilient RVs

But the revolution doesn’t stop there. As if 3D printing wasn’t enough to get your motor running, the world of advanced materials is also transforming the RV industry. Gone are the days of heavy, clunky recreational vehicles that guzzle fuel and struggle to navigate the winding roads of the great outdoors. Today, we’re seeing a new generation of RVs built with lightweight, durable composites that offer unparalleled strength and resilience.

Take, for example, the latest generation of fiberglass-reinforced plastic (FRP) panels. These cutting-edge materials are not only incredibly strong and impact-resistant, but they also weigh a fraction of the traditional plywood and aluminum used in RV construction. This translates to better fuel efficiency, improved handling, and a more comfortable ride for you and your passengers. And when it comes to maintenance, these advanced materials are a dream come true. No more worrying about rust, rot, or dents – our FRP-clad RVs shrug off the elements like a duck taking a dip in the pond.

Embracing the Future: Challenges and Opportunities

Of course, with any technological revolution, there are always challenges to overcome. As we dive headfirst into the world of 3D printing and advanced materials, we’ve had to navigate a steep learning curve and overcome a few unexpected hurdles. Sourcing the right raw materials, calibrating our printers to perfection, and keeping up with the breakneck pace of innovation – it’s all part of the job. But let me tell you, the rewards far outweigh the challenges.

Just the other day, I had a customer come in with a wonky slideout mechanism that was causing all sorts of grief. In the past, we’d have had to order a replacement part and wait for it to arrive, leaving the poor RV owner stranded and inconvenienced. But with our 3D printing capabilities, we were able to quickly diagnose the issue, design a custom replacement part, and have the slideout up and running in a matter of hours. The customer was overjoyed, praising our team’s ingenuity and problem-solving skills. It’s moments like these that make all the hard work worth it.

Forging Ahead: The Future of RV Maintenance

As I look to the horizon, I can’t help but feel a sense of excitement and anticipation for the future of RV maintenance. The possibilities are truly endless, my friends. Imagine a world where 3D-printed replacement parts are as common as a trip to the grocery store, where advanced composite materials make our RVs lighter, stronger, and more resilient than ever before. It’s a future that’s not only more convenient and cost-effective for RV owners, but also better for the environment as we reduce waste and minimize our carbon footprint.

And the best part? We’re not just talking about some distant, pie-in-the-sky vision. This future is already taking shape right here at our RV repair shop in Orange County. We’re on the cutting edge of innovation, constantly exploring new technologies, materials, and techniques to push the boundaries of what’s possible. So whether you’re a seasoned RV enthusiast or just getting started on your mobile adventure, I invite you to join us on this journey. Together, let’s forge a brighter, more resilient future for the RV community – one 3D-printed part and lightweight composite at a time.