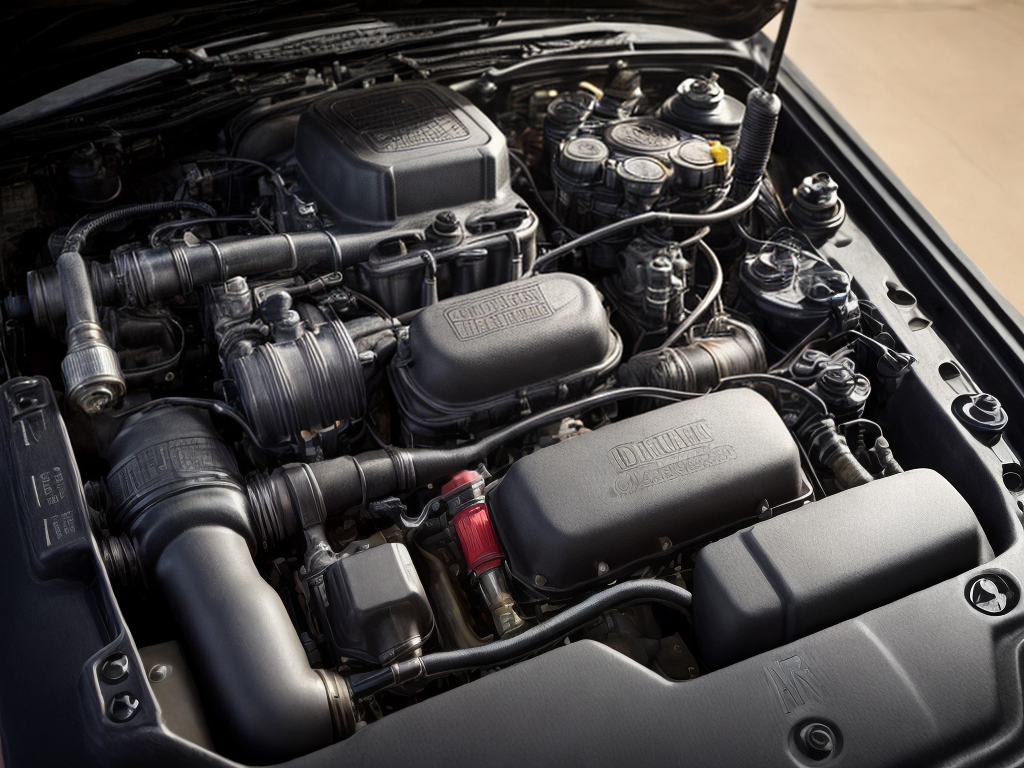

I’ve always been fascinated by the inner workings of diesel engines. The rhythmic hum and the power they produce are truly remarkable. But, like any complex machinery, they require regular maintenance and occasional troubleshooting. In this comprehensive tutorial, I’ll guide you through the essential tasks and common issues, from oil changes to fuel system maintenance. By understanding these intricacies, you can prolong the lifespan of your diesel engine and keep it running smoothly for years to come.

Understanding Diesel Engines

To fully comprehend the inner workings of diesel engines, one must first understand the fundamental principles behind their operation. Understanding diesel mechanics is crucial for anyone working with or owning a diesel engine. Unlike gasoline engines, which rely on spark ignition, diesel engines use compression ignition. This means that instead of a spark plug igniting the fuel-air mixture, the heat generated by compressing the air in the combustion chamber causes the fuel to ignite. This method allows diesel engines to be more fuel-efficient and have higher torque than gasoline engines. Additionally, diesel engines are known for their durability and longevity, making them ideal for heavy-duty applications such as in trucks and industrial machinery. Overall, understanding the mechanics and benefits of diesel engines is essential for effectively maintaining and troubleshooting these powerful and efficient machines.

Essential Maintenance Tasks

As a diesel engine owner, it is crucial to stay on top of essential maintenance tasks to ensure optimal performance and longevity. Three key maintenance tasks that should not be overlooked are oil change frequency, fuel filter replacement, and cooling system maintenance. Regularly changing the oil based on manufacturer recommendations is vital to prevent engine damage and maintain proper lubrication. Additionally, replacing the fuel filter at recommended intervals is crucial to prevent contaminants from reaching the engine. Finally, maintaining the cooling system by regularly checking coolant levels and inspecting hoses and belts helps prevent overheating and potential engine failure.

Oil Change Frequency

I change the oil in my diesel engine every 5,000 miles to ensure proper lubrication and prevent engine damage. The oil change interval is a critical maintenance task that should not be overlooked. Regularly changing the oil helps remove dirt, debris, and contaminants that can accumulate over time and impact engine performance. When it comes to choosing the right oil for your diesel engine, there are two options: synthetic and conventional oil. Synthetic oil offers several advantages over conventional oil, including better resistance to breakdown, improved engine protection, and enhanced fuel efficiency. However, it tends to be more expensive. Conventional oil, on the other hand, is more affordable but may require more frequent oil changes. Ultimately, the choice between synthetic and conventional oil depends on your budget and specific engine requirements.

Fuel Filter Replacement

Continuing with the essential maintenance tasks for diesel engines, a crucial aspect to address is the replacement of the fuel filter. The fuel filter plays a vital role in ensuring that clean fuel reaches the engine, preventing contaminants from causing damage. Regular fuel filter maintenance is necessary to keep the engine running smoothly and efficiently. Here are three signs that indicate a clogged fuel filter:

- Engine Misfires: A clogged fuel filter can restrict the flow of fuel to the engine, resulting in misfires. This can cause a decrease in engine performance and a rough idle.

- Difficulty Starting: A clogged fuel filter can make it harder for the engine to start, as the fuel flow is restricted. If you notice prolonged cranking or difficulty starting the engine, it may be a sign of a clogged filter.

- Decreased Fuel Efficiency: A clogged fuel filter can lead to a decrease in fuel efficiency. If you find that you are getting fewer miles per gallon than usual, it might be time to replace the fuel filter.

Regular fuel filter maintenance and timely replacement is essential to ensure optimal engine performance and prevent potential damage.

Cooling System Maintenance

Maintaining the cooling system is crucial for optimal diesel engine performance and preventing overheating. Two essential maintenance tasks for the cooling system are coolant flush and radiator maintenance.

To perform a coolant flush, start by draining the old coolant from the radiator. Locate the drain plug at the bottom of the radiator and open it to let the coolant flow out into a container. Once all the coolant is drained, close the drain plug and refill the radiator with a mixture of coolant and water according to the manufacturer’s specifications.

Radiator maintenance involves cleaning the radiator fins to ensure proper airflow. Start by removing any debris or dirt from the radiator fins using a soft brush or compressed air. Be careful not to damage the fins. If the fins are bent, use a fin comb to straighten them out.

Regularly performing these maintenance tasks will help keep the cooling system in good condition, preventing overheating and ensuring optimal diesel engine performance.

Troubleshooting Common Issues

One might encounter various common issues when troubleshooting a diesel engine. Here are three common problems that can arise:

- Starting problems: A diesel engine may fail to start due to issues with the fuel system, such as a clogged fuel filter or a faulty fuel pump. Additionally, problems with the glow plugs, which help ignite the fuel, can also prevent the engine from starting.

- Idling issues: When a diesel engine struggles to maintain a steady idle, it could be caused by a variety of factors. Common culprits include a malfunctioning idle control valve, dirty fuel injectors, or a faulty throttle position sensor.

- Air intake problems: If the engine is not getting enough air, it may exhibit symptoms such as rough idling or difficulty starting. Issues with the air filter, intake manifold, or turbocharger can all contribute to inadequate airflow.

Importance of Regular Oil Changes

Regular oil changes are a crucial aspect of maintaining a diesel engine’s performance and longevity. Neglected oil changes can have a significant impact on the engine’s overall health and efficiency. The benefits of regular oil changes cannot be overstated. First and foremost, oil changes ensure that the engine’s moving parts are properly lubricated, reducing friction and wear. Clean oil also helps to remove harmful contaminants and debris that can accumulate over time, preventing them from causing damage to the engine. Additionally, fresh oil helps to cool the engine, preventing it from overheating and extending its lifespan. Neglecting oil changes can result in decreased fuel efficiency, increased emissions, and even engine failure. Therefore, it is imperative to adhere to the manufacturer’s recommended oil change intervals to keep the engine running smoothly.

Fuel System Maintenance Tips

When it comes to maintaining the fuel system in a diesel engine, there are several important points to keep in mind. First, regular filter replacement is crucial to ensure proper fuel flow and prevent contaminants from entering the engine. Secondly, using fuel additives can help improve performance by cleaning injectors and reducing fuel system deposits. Lastly, being aware of common fuel system issues such as fuel leaks or clogged injectors can help troubleshoot and address problems before they worsen. By following these tips, you can ensure the longevity and efficiency of your diesel engine’s fuel system.

Filter Replacement Importance

I always make sure to regularly swap out the filters in my diesel engine’s fuel system to maintain its optimal performance. Filter replacement is a crucial aspect of diesel engine maintenance, as it helps prevent contaminants from reaching the engine and causing damage. Here are three reasons why filter replacement is so important:

- Filter Replacement Interval: Filters have a limited lifespan and need to be replaced at regular intervals. The specific interval will depend on the manufacturer’s recommendations and the conditions in which the engine operates. Neglecting to replace the filters on time can lead to reduced fuel efficiency, engine misfires, and even engine failure.

- Signs of a Clogged Filter: It is essential to be aware of the signs indicating a clogged filter. These may include reduced engine power, difficulty starting the engine, increased exhaust emissions, and a decrease in fuel efficiency. Regularly inspecting the filters and replacing them when necessary can help prevent these issues.

- Protecting the Fuel System: Filters play a crucial role in protecting the fuel system from contaminants such as dirt, debris, and water. By replacing the filters, you ensure that these harmful particles are captured and prevented from entering the engine. This helps maintain the fuel system’s integrity and prolongs the life of the engine.

Fuel Additives for Performance

Continuing the discussion on the importance of filter replacement, it is crucial to consider the role of fuel additives in maintaining optimal performance and prolonging the life of your diesel engine’s fuel system. Fuel additives are chemical compounds that are mixed with diesel fuel to improve its properties and enhance engine performance. There are various types of fuel additives available in the market, each designed to address specific issues. Some additives focus on improving fuel efficiency by reducing friction and improving combustion, while others target emissions reduction by lowering harmful pollutants. By using fuel additives regularly, you can ensure that your diesel engine operates at its best, achieving maximum fuel efficiency and minimizing its environmental impact. It is important to follow manufacturer recommendations when selecting and using fuel additives to ensure compatibility with your engine and to avoid any potential damage.

Common Fuel System Issues

Addressing common fuel system issues is essential for maintaining the optimal performance and longevity of a diesel engine. To ensure that the fuel system is functioning properly, it is important to perform regular fuel system diagnostics. This involves checking for any leaks, inspecting the fuel lines and filters, and monitoring fuel pressure. Additionally, fuel injector cleaning is crucial to prevent clogging and maintain efficient fuel delivery. Here are three fuel system maintenance tips:

- Use high-quality fuel additives: Additives can help remove deposits and prevent the buildup of carbon and varnish in the fuel system.

- Replace fuel filters regularly: Dirty fuel filters can restrict fuel flow and cause engine performance issues. It is recommended to replace them according to the manufacturer’s guidelines.

- Maintain proper fuel storage: Ensure that fuel is stored in a clean, moisture-free environment to prevent contamination and deterioration.

Cooling System Maintenance Guide

To effectively maintain a diesel engine’s cooling system, regular inspection and maintenance of its components are crucial. One important aspect of cooling system maintenance is performing a coolant flush procedure. This involves draining the old coolant from the system and replacing it with fresh coolant. It is recommended to follow the manufacturer’s guidelines for the proper coolant to use and the frequency of coolant flushes. Additionally, radiator cleaning techniques are essential to keep the cooling system functioning optimally. Regularly cleaning the radiator helps remove debris, dirt, and other contaminants that can obstruct the flow of air and reduce the cooling efficiency. This can be done by using a soft brush or compressed air to remove the buildup on the surface of the radiator fins.

| Maintenance Tips | Description |

|---|---|

| Coolant Flush Procedure | Draining and replacing the old coolant with fresh coolant according to the manufacturer’s guidelines. |

| Radiator Cleaning Techniques | Removing debris, dirt, and contaminants from the radiator to ensure optimal cooling efficiency. |

Electrical System Troubleshooting

Now, let’s delve into troubleshooting the electrical system of a diesel engine. When it comes to electrical system failures, it is important to follow a systematic approach in order to identify and resolve the issue. Here are three key troubleshooting techniques to help you in this process:

- Check the battery: Start by inspecting the battery for any signs of damage or corrosion. Use a multimeter to measure the battery voltage and ensure it is within the recommended range. If the voltage is low, recharge or replace the battery accordingly.

- Inspect the wiring: Examine the wiring harness for any loose connections, frayed wires, or damaged insulation. Pay close attention to areas where the wiring may come into contact with other components or sharp edges. Repair or replace any faulty wiring as necessary.

- Test the components: Use a digital voltmeter to test the voltage at various electrical components, such as the alternator, starter motor, and ignition system. Compare the readings to the specifications provided by the manufacturer. Replace any faulty components that are not functioning within the recommended range.

Preventing and Fixing Overheating

I’ll start by discussing the importance of coolant system maintenance in preventing and fixing overheating issues. Regularly checking coolant levels, inspecting for leaks, and flushing the system at recommended intervals are key steps to ensure proper engine cooling. Next, I’ll delve into identifying common causes of overheating, such as a malfunctioning thermostat, a faulty water pump, or a clogged radiator. Finally, I’ll provide effective solutions for overheating, including replacing faulty components, cleaning or replacing the radiator, and flushing the coolant system to remove any debris or contaminants.

Coolant System Maintenance

One can easily prevent and fix overheating in a diesel engine by properly maintaining the coolant system. Here are three key steps to ensure the optimal performance of your coolant system:

- Coolant System Flush: Regularly flushing the coolant system helps remove any built-up contaminants, such as rust, scale, or sediment. This prevents clogs and improves the overall efficiency of the system. A coolant system flush should be performed every 2-3 years or as recommended by the manufacturer.

- Radiator Maintenance: The radiator plays a crucial role in regulating the engine temperature. It is important to inspect the radiator for any signs of damage, such as leaks or blockages, and address them promptly. Additionally, ensure that the radiator is kept clean and free from debris by regularly cleaning the fins and using a radiator cleaner.

- Coolant Level and Quality: Check the coolant level regularly and add a 50/50 mixture of antifreeze and distilled water if needed. Also, monitor the quality of the coolant to ensure it is free from contaminants and has the appropriate chemical composition for optimal heat transfer and corrosion protection.

Identifying Common Causes

To identify common causes and effectively prevent and fix overheating in a diesel engine, it is crucial to understand the key factors that contribute to this issue. Overheating can lead to serious damage to the engine if not addressed promptly. Common symptoms of overheating include an increase in engine temperature, steam coming from the radiator, and a strong smell of coolant. When troubleshooting overheating issues, it is important to check the coolant level and quality, inspect the radiator for any blockages or leaks, and ensure that the cooling fan is functioning properly. Other potential causes of overheating include a faulty thermostat, a malfunctioning water pump, or a clogged radiator. By following these troubleshooting techniques and addressing any issues promptly, you can effectively prevent and fix overheating in your diesel engine.

Effective Overheating Solutions

To effectively prevent and fix overheating in a diesel engine, it is essential to implement effective solutions that address the root causes of this issue. Here are three effective cooling methods to consider:

- Maintain Proper Coolant Levels: Regularly check and top up the coolant levels in your engine. Coolant helps regulate the temperature and prevents overheating. If the coolant level is low, it can lead to overheating.

- Clean and Inspect the Radiator: The radiator plays a crucial role in cooling the engine. Over time, it can accumulate dirt, debris, and corrosion, hindering its effectiveness. Regularly clean and inspect the radiator for any blockages or damage.

- Check the Cooling Fan: The cooling fan helps dissipate heat from the engine. Ensure that it is functioning properly by checking for any signs of damage or wear. Replace any faulty cooling fans promptly.

Addressing Starting and Idling Problems

When diagnosing and resolving starting and idling problems in diesel engines, a thorough inspection of the fuel system is essential. Starting problems can be caused by issues such as air in the fuel lines, a faulty fuel pump, or clogged fuel filters. To address these issues, it is important to check for any leaks or cracks in the fuel lines, ensure the fuel pump is functioning properly, and replace any clogged filters. Idling issues, on the other hand, can be caused by a variety of factors including a malfunctioning idle control valve, dirty injectors, or a faulty throttle position sensor. To resolve idling problems, it is crucial to inspect and clean the idle control valve, clean or replace the injectors, and test the throttle position sensor for any faults. By carefully inspecting and addressing these fuel system components, starting and idling problems in diesel engines can be effectively resolved.

Extending the Lifespan of Your Diesel Engine

To ensure the longevity of my diesel engine, I prioritize regular maintenance and adhere to manufacturer guidelines. By following these diesel engine maintenance techniques, I can extend the engine’s lifespan and avoid costly repairs or replacements. Here are three key steps I take to keep my diesel engine in optimal condition:

- Regular oil changes: Changing the engine oil at recommended intervals ensures proper lubrication, reduces wear and tear, and prevents engine damage. I use high-quality oil that meets the manufacturer’s specifications.

- Fuel system maintenance: I clean or replace fuel filters regularly to prevent contaminants from clogging the injectors. Additionally, I use fuel additives to improve fuel quality and reduce the risk of injector deposits.

- Cooling system care: Maintaining the correct coolant level and regularly flushing the cooling system prevents overheating and corrosion. I also check for leaks and ensure that the radiator fins are clean and free from debris.

Following these maintenance techniques helps me maximize the lifespan of my diesel engine and keep it running smoothly for years to come.