The Dreaded Head Gasket Dilemma

As the owner of an RV and fleet vehicle repair shop in sunny Orange County, California, I’ve seen my fair share of automotive woes. But one issue that always sends a shiver down my spine? The dreaded head gasket leak. It’s like that annoying relative who always shows up unannounced – you know it’s coming, you dread it, and you just wish it would go away. But alas, it’s an all-too-common problem, and one that needs to be addressed head-on (no pun intended).

I remember this one time, we had a client come in with an old RV that was chugging along like a locomotive on its last legs. The poor thing was billowing out more smoke than a California wildfire, and the coolant level was dropping faster than a lead balloon. I knew right away we were dealing with a classic case of a leaky head gasket.

As I dug into the problem, I could practically see the dollar signs dancing in my head. Head gasket repairs can be a real pain in the you-know-what, not to mention a major hit to the wallet. But I also knew that ignoring the issue would only lead to bigger problems down the line. So, I rolled up my sleeves and got to work, determined to get this RV back on the road and back to its old self.

Understanding the Head Gasket

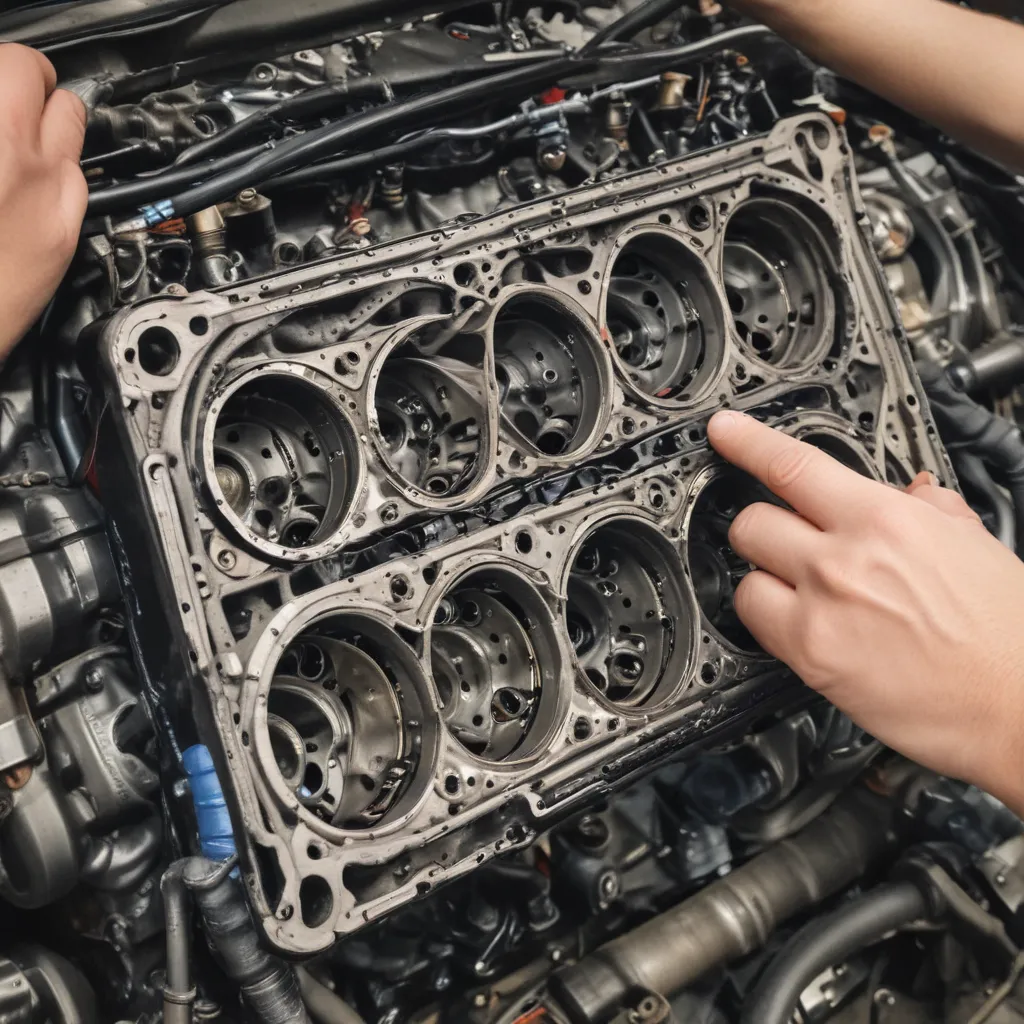

Now, before we dive into the nitty-gritty of the block test, let’s first take a moment to appreciate the importance of the head gasket and why it’s such a critical component in your vehicle’s engine.

The head gasket is essentially the unsung hero of the engine. It sits between the engine block and the cylinder head, forming a tight seal that keeps all the essential fluids and gases where they’re supposed to be. Its primary job is to prevent the engine coolant and oil from mixing, which would be a recipe for disaster.

Imagine if your engine was a leaky boat, with the coolant and oil sloshing around like a stormy sea. It would be a complete and utter mess, leading to all sorts of problems – engine overheating, increased wear and tear, and even total engine failure. That’s why the head gasket is so crucial; it’s the glue that holds everything together and keeps your engine running smoothly.

Identifying the Signs of a Leaking Head Gasket

Of course, even the mightiest head gasket can’t last forever. Over time, the constant heat and pressure inside the engine can take their toll, causing the gasket to degrade and eventually fail. And when that happens, it’s time to break out the tools and get to work.

But how can you tell if your head gasket is on its last legs? Well, there are a few telltale signs to look out for:

Coolant Loss: If you find yourself constantly topping up the coolant reservoir, it’s a sure-fire sign that you’ve got a leak somewhere. And if the coolant is looking particularly milky or discolored, that’s a dead giveaway that the coolant and oil are mixing.

Engine Overheating: When that head gasket starts to go, it can cause the engine to overheat, even if you’ve got a full coolant system. This is because the leaking coolant can’t effectively circulate and dissipate the heat.

White Exhaust Smoke: If you notice a plume of white smoke coming from the tailpipe, it could mean that the combustion gases are escaping through the head gasket and mixing with the coolant.

Oil Contamination: Similarly, if the oil is looking a little on the frothy side or has taken on a creamy appearance, it’s a clear indication that the coolant and oil are cross-contaminating.

Now, I know what you’re thinking – “But wait, those all sound like pretty serious problems! Surely there’s an easier way to diagnose a head gasket issue?” Well, my friends, that’s where the block test comes into play.

The Block Test: Diagnosing Head Gasket Leaks

The block test is a nifty little diagnostic tool that can help you pinpoint a leaking head gasket with laser-like precision. It’s a simple, yet effective way to identify the problem without having to tear the entire engine apart.

Here’s how it works:

Prepare the Engine: First, you’ll need to make sure the engine is at operating temperature. This means letting it run for a good 15-20 minutes, or until the cooling system is fully warmed up.

Pressurize the Cooling System: Next, you’ll need to pressurize the cooling system. This can be done using a special tool called a cooling system pressure tester, which you can typically rent or borrow from your local auto parts store.

Inspect for Bubbles: Once the system is pressurized, start carefully inspecting the engine block, cylinder head, and any other potential leak points. If you see any bubbles forming, that’s a clear sign of a head gasket leak.

Identify the Leak Location: By paying close attention to where the bubbles are forming, you can actually pinpoint the exact location of the leak. This information is invaluable when it comes to determining the best course of repair.

Now, I know what you’re thinking – “That’s all well and good, but what if I don’t have a cooling system pressure tester?” Well, fear not, my fellow auto enthusiasts, because there’s an alternative method that can work just as well.

The Alternate Compression Test Method

If you don’t have access to a dedicated cooling system pressure tester, you can actually use a compression tester to achieve the same results. Here’s how:

Prepare the Engine: Just like with the block test, make sure the engine is at operating temperature before you begin.

Remove the Spark Plugs: Next, you’ll need to remove the spark plugs from the engine. This will allow you to easily insert the compression tester into each cylinder.

Perform the Compression Test: With the spark plugs out, start the engine and let it run for a few seconds. Then, quickly insert the compression tester into each cylinder and take a reading. If you notice any significant drops in compression across the cylinders, it could be a sign of a head gasket leak.

Interpret the Results: By comparing the compression readings across the different cylinders, you can often pinpoint the location of the leak. If one or more cylinders are showing significantly lower readings, that’s a strong indication of a head gasket issue.

Now, I know what you’re thinking – “But wait, won’t this method also show issues with other engine components, like worn piston rings or valves?” And you’d be absolutely right. The compression test is a more general diagnostic tool, and it can reveal a variety of engine problems, not just head gasket leaks.

That’s why it’s important to use the compression test in conjunction with the block test, if possible. The block test will give you a more definitive answer as to whether the head gasket is the culprit, while the compression test can help you identify any additional issues that may be present.

Real-World Case Studies: Tackling Head Gasket Leaks

Alright, now that we’ve covered the theory, let’s dive into some real-world examples of how I’ve tackled head gasket leaks in the past. After all, what good is all this knowledge if we can’t put it into practice?

One of the most memorable cases I had was with an old Ford F-150 that had been in the family for years. The poor thing was chugging along like a steam locomotive, and the coolant level was dropping faster than a stone. I knew we were dealing with a classic head gasket issue, so I got to work.

First, I performed the block test, and sure enough, I saw those telltale bubbles forming around the cylinder head. After further inspection, I was able to pinpoint the exact location of the leak, which turned out to be on the driver’s side of the engine.

Now, I could have just gone ahead and replaced the head gasket, but I wanted to be absolutely certain that there weren’t any other underlying issues. So, I decided to also run a compression test, just to be on the safe side.

To my surprise, the compression test revealed that a couple of the cylinders were also low on compression. This indicated that there might be some additional problems, like worn piston rings or valves, that needed to be addressed.

Long story short, we ended up having to do a full engine rebuild on that old F-150. It was a time-consuming and costly process, but in the end, it was the right call. The customer was thrilled to have their trusty truck back on the road, running better than ever.

Another case that sticks out in my mind was with a client who brought in their RV for a routine maintenance check. Now, this RV was no spring chicken – it had been through the wringer and back, and the owner was starting to get a little nervous about its longevity.

During the inspection, I noticed that the coolant level was a bit on the low side, and there were some suspicious-looking stains around the engine block. So, I decided to run the block test, just to be safe.

Sure enough, the block test revealed a small but persistent leak in the head gasket. The good news was that it was a relatively minor issue, and we were able to address it with a simple head gasket replacement.

The customer was relieved, to say the least. They had been dreading the idea of a major engine overhaul, but thanks to the block test, we were able to identify and fix the problem quickly and efficiently. They were back on the road in no time, with a renewed sense of confidence in their trusty RV.

Wrapping it Up: The Importance of Proactive Maintenance

At the end of the day, dealing with a leaking head gasket is never a fun experience. It’s a tricky and often costly problem that can quickly escalate if left unchecked. But with the right diagnostic tools and a little bit of know-how, it doesn’t have to be a nightmare.

The key is to stay proactive and on top of your vehicle’s maintenance. Regular inspections, coolant flushes, and being vigilant for any signs of trouble can go a long way in preventing major head gasket issues down the line.

And if you do find yourself faced with a head gasket leak, don’t panic! Take a deep breath, grab your tools, and get to work. With the block test and compression test in your arsenal, you’ll be able to quickly identify the problem and get your vehicle back on the road in no time.

So, the next time you hear that familiar hissing sound or see the coolant level dropping faster than a skydiver, don’t ignore it! Hop on over to Orange County RV Repair and let us put our expertise to work. We’ll have your RV or fleet vehicle purring like a kitten in no time, head gasket leak-free and ready to take on the open road.