The Dreaded Click: Diagnosing a Faulty Starter Motor

Picture this: you turn the key in the ignition, and instead of the familiar roar of your RV’s engine coming to life, you’re greeted by a disheartening ‘click.’ It’s a sound that can send a chill down any RV owner’s spine, and it’s often the telltale sign of a malfunctioning starter motor. As the owner of an RV and fleet repair company in Orange County, California, I’ve seen my fair share of these pesky problems. But don’t worry, my friends, I’m here to guide you through the ins and outs of troubleshooting and resolving those dreaded starter motor issues.

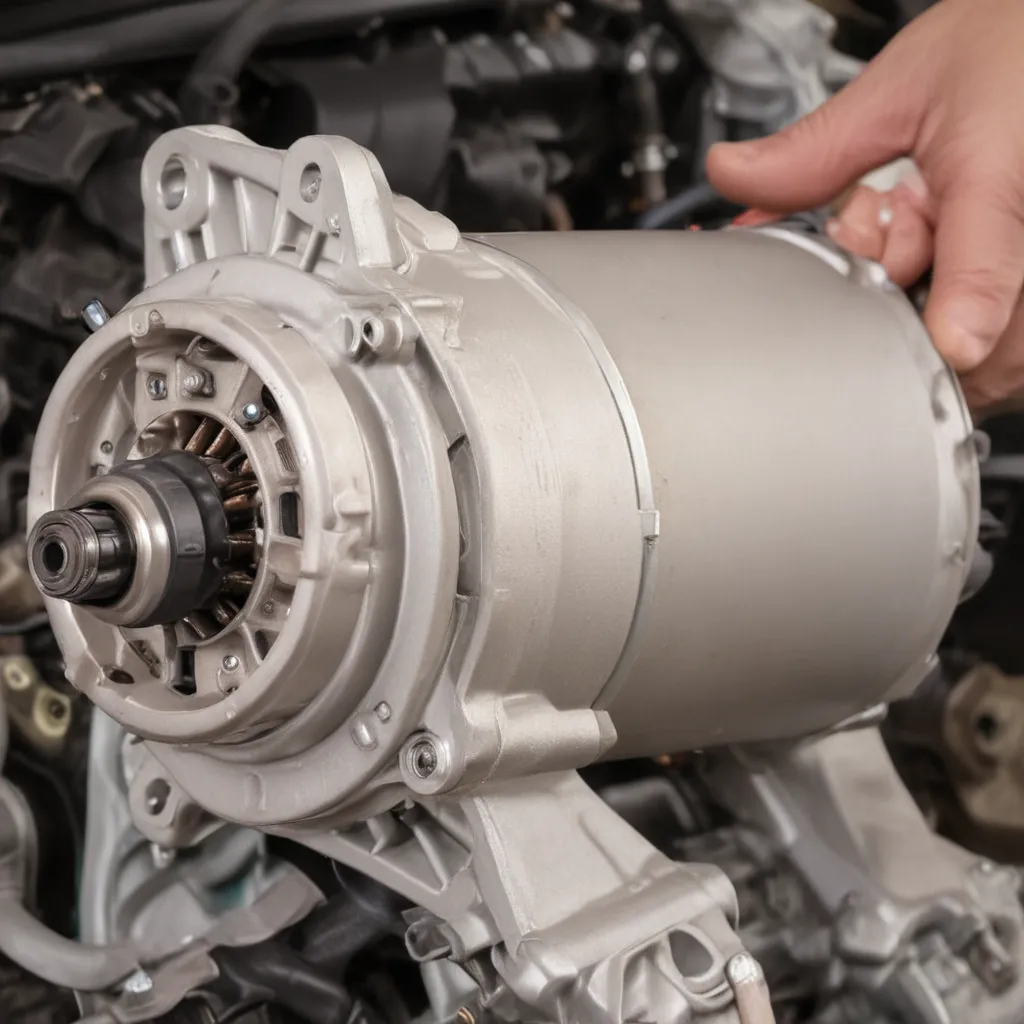

Let me start by saying that your starter motor is a crucial component of your vehicle’s electrical system. It’s the unsung hero that transforms the electrical energy from your battery into the mechanical force needed to crank the engine and get your RV or fleet vehicle up and running. When it’s working properly, it’s easy to take for granted. But when it starts to act up, it can quickly become the bane of your existence.

Identifying the Symptoms of a Failing Starter Motor

So, how do you know if your starter motor is on its last legs? Well, the good news is that the signs are usually pretty easy to spot. The most common symptom is the dreaded ‘click’ we mentioned earlier – that telltale sound that lets you know something isn’t quite right. But that’s not the only thing to watch out for. Other signs of a failing starter motor include:

- Slow or sluggish engine cranking

- The engine not starting at all, even when the battery is fully charged

- Grinding or whirring noises coming from the engine bay

- Your dashboard lights flickering or dimming when you turn the key

If you’re experiencing any of these issues, it’s a good idea to have your starter motor checked out by a professional as soon as possible. Ignoring the problem can lead to further damage and even more expensive repairs down the line.

Uncovering the Causes of Starter Motor Failure

Now that we’ve covered the symptoms, let’s dive into the root causes of starter motor failure. There are a few common culprits that can lead to this frustrating problem:

Worn or Damaged Brushes: The starter motor relies on a set of carbon brushes to transmit the electrical current from the battery to the armature. Over time, these brushes can become worn down or damaged, leading to poor electrical contact and a malfunctioning starter.

Faulty Solenoid: The solenoid is the component that actually engages the starter motor when you turn the key. If the solenoid is failing, it can prevent the starter from engaging properly.

Corrosion and Loose Connections: The starter motor is connected to your battery and other electrical components through a series of cables and connections. If these connections become corroded or loose, it can disrupt the flow of electricity and cause the starter to malfunction.

Mechanical Issues: Sometimes, the problem isn’t electrical at all. The starter motor itself can experience mechanical wear and tear, such as worn bearings or a seized armature, which can prevent it from spinning as it should.

Identifying the root cause of your starter motor issues is crucial, as it will determine the best course of action for getting your vehicle back on the road. That’s why it’s always a good idea to have a professional technician take a look – they’ll have the tools and expertise to pinpoint the problem and recommend the right solution.

Troubleshooting and Diagnosing Starter Motor Problems

Now that we’ve covered the common symptoms and causes of starter motor failure, let’s talk about how to actually go about troubleshooting and diagnosing the issue. Here’s a step-by-step guide to help you get to the bottom of the problem:

Check the Battery: The first step is to make sure your battery is in good condition and properly charged. A weak or dead battery can prevent the starter motor from receiving the necessary electrical current to function correctly.

Inspect the Connections: Look for any signs of corrosion or loose connections in the starter motor’s wiring. Clean the connections and tighten any loose bolts or terminals.

Listen for the Solenoid: When you turn the key in the ignition, you should hear a distinct ‘click’ from the solenoid. If you don’t hear this click, or if the sound is weak or delayed, the solenoid may be the culprit.

Test the Starter Motor: If the battery and connections check out, the next step is to test the starter motor itself. You can do this by using a multimeter to check for proper voltage and resistance readings.

Perform a Load Test: Another way to diagnose a starter motor issue is to perform a load test. This involves using a specialized tool to apply a load to the starter and measure its performance under stress.

Check for Mechanical Wear: If the electrical components all seem to be in good working order, the problem may be mechanical in nature. Inspect the starter motor for any signs of wear, such as a seized armature or worn bearings.

By following this step-by-step process, you’ll be well on your way to identifying the root cause of your starter motor issues and getting your RV or fleet vehicle back on the road.

Repairing or Replacing the Starter Motor

Once you’ve identified the problem, it’s time to take action. Depending on the severity of the issue, you may be able to repair the starter motor or you may need to replace it entirely. Here’s a quick rundown of your options:

Repairing the Starter Motor

If the issue is something relatively minor, such as a faulty solenoid or worn brushes, you may be able to repair the starter motor rather than replace it. This is often the more cost-effective option, as long as the core components of the motor are still in good shape.

The process of repairing a starter motor typically involves:

- Disassembling the motor and inspecting the internal components

- Replacing any worn or damaged parts, such as the brushes or solenoid

- Cleaning and lubricating the remaining components

- Reassembling the motor and testing it to ensure it’s working properly

Replacing the Starter Motor

If the starter motor is beyond repair, or if the cost of the repair is too high, the best course of action may be to replace the entire unit. This is a more involved process that requires:

- Disconnecting the old starter motor from the engine and electrical system

- Installing the new starter motor and reconnecting all the necessary wiring and cables

- Ensuring the new starter is properly aligned and secured

- Testing the new starter to make sure it’s functioning as it should

Now, I know what you might be thinking – “But wait, doesn’t replacing the starter motor sound like a huge pain?” And you’d be absolutely right. It’s a job that can be quite complex, especially on larger RVs or fleet vehicles. That’s why I always recommend having a professional technician handle the repair or replacement process.

At our RV and fleet repair shop in Orange County, California, we have a team of highly trained and experienced mechanics who specialize in starter motor issues. They have the tools, the knowledge, and the expertise to get the job done quickly and efficiently, so you can get back on the road as soon as possible.

Preventative Maintenance: Keeping Your Starter Motor in Top Shape

Of course, the best way to deal with starter motor problems is to prevent them from happening in the first place. That’s where preventative maintenance comes in. By taking a proactive approach, you can help extend the life of your starter motor and avoid those dreaded breakdowns down the road.

Here are a few key tips for keeping your starter motor in top shape:

Regular Inspections: Have your starter motor checked during routine maintenance visits. This will allow your technician to catch any early signs of wear or damage before they turn into a bigger problem.

Clean and Protect Connections: Keep the starter motor’s electrical connections clean and free of corrosion. Use a wire brush or sandpaper to remove any built-up grime, and consider applying a protective coating to help prevent future corrosion.

Monitor Battery Health: As we mentioned earlier, a weak or dying battery can be a major contributor to starter motor issues. Make sure to have your battery tested and replaced if necessary.

Avoid Excessive Cranking: If your engine is taking a long time to start, resist the urge to keep cranking the starter. This can put unnecessary strain on the motor and lead to premature wear.

By following these simple maintenance tips, you can help ensure that your starter motor keeps on ticking for years to come. And if you ever do run into any issues, don’t hesitate to bring your RV or fleet vehicle to our shop in Orange County. We’re always here to lend a hand and get you back on the road as quickly and painlessly as possible.

Conclusion: Mastering the Art of Starter Motor Troubleshooting

Well, there you have it, my friends – a comprehensive guide to troubleshooting and resolving those pesky starter motor problems. From identifying the symptoms to uncovering the root causes, and from repairing the motor to keeping it in top shape through preventative maintenance, I’ve covered it all.

As the owner of an RV and fleet repair company in Orange County, California, I’ve seen my fair share of these issues over the years. But I can tell you with certainty that when it comes to starter motor problems, knowledge is power. The more you understand about how these critical components work and what can go wrong, the better equipped you’ll be to tackle any issues that come your way.

So, the next time you hear that dreaded ‘click’ when you turn the key, don’t panic. Take a deep breath, run through the troubleshooting steps we’ve covered, and don’t be afraid to reach out to a professional if you need a little extra help. With the right approach, you’ll have your RV or fleet vehicle back on the road in no time.

And if you’re ever in the Orange County area and need a little assistance with your starter motor or any other RV or fleet vehicle repair, be sure to head on over to https://orangecountyrvrepair.com/. We’d be more than happy to lend a hand and get you back to exploring the open road.